ince 2013, Scala Filtration has been delivering quality compressed air purification equipment and laboratory liquid nitrogen generators around the world.

To lean more about latest technology and solution to compressed air treatment and liquid nitrogen generation,please contact us immediately.

Compressed Air Treatment & Liquid Nitrogen Generator

Language:

Oil-Less Scroll Airend

Oil-free Scroll Air End

Our Oil-free Scroll Air Ends are more than just components; they are guardians of air quality and reliability, serving critical industrial needs. Whether your focus is on maintaining the utmost air purity for sensitive processes or adhering to stringent environmental standards, Scala's Oil-free Scroll Air Ends stand as paragons of excellence.

Our Oil-free Scroll Air Ends are not just products, but solutions sculpted for industries where oil-free and untainted air is non-negotiable. Available in power variations of 2.2kW, 3.0kW, 3.7kW, 5.5kW and 7.5kW, they assure unwavering performance under both 8 and 10 bar pressures.

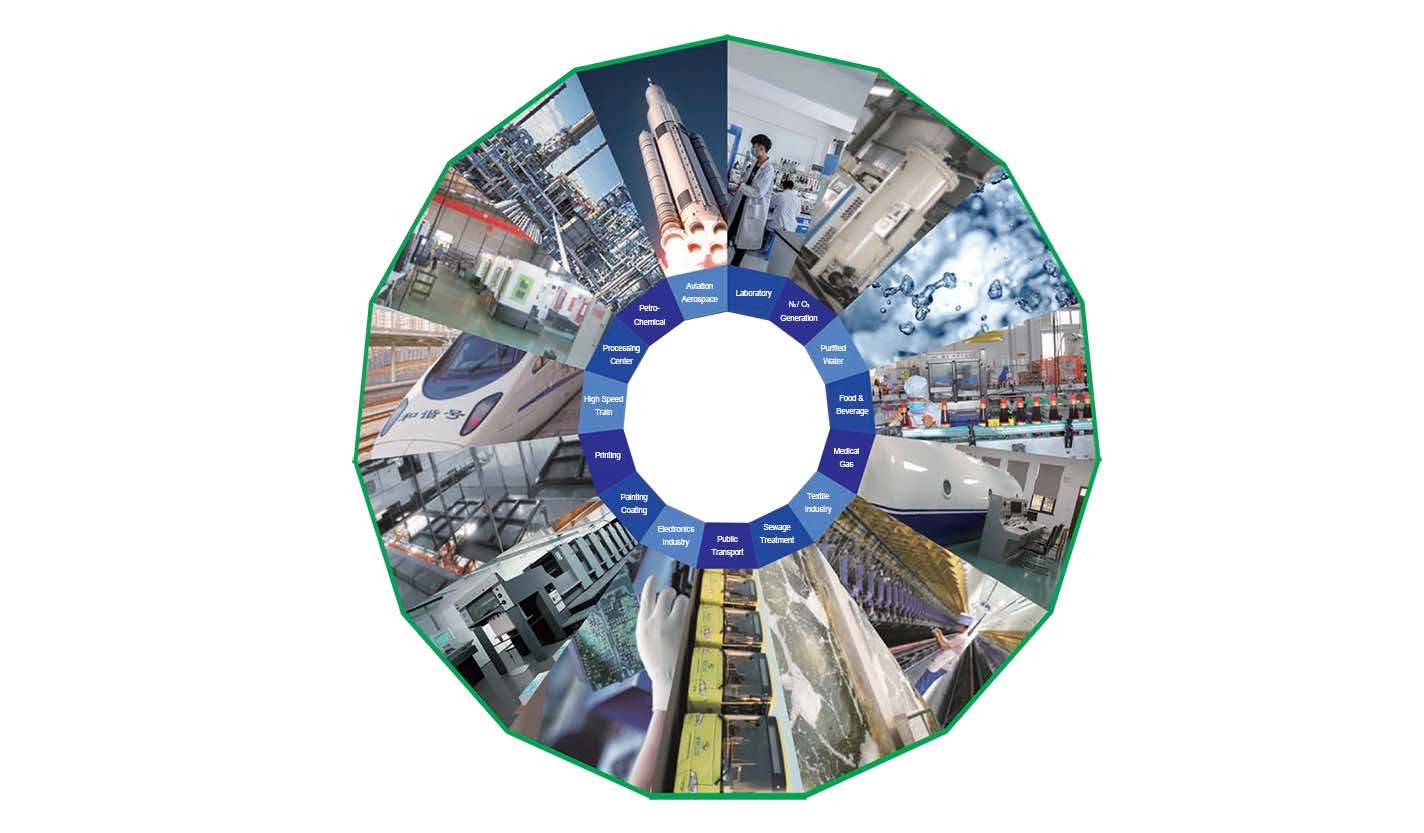

Applications

Oil-free scroll air-end technology is widely used in applications where clean, contaminant-free compressed air is critical. Since oil-free scroll compressors do not use oil for lubrication or sealing, they are ideal for industries that require high air purity. The key applications of oil-free scroll air-end technology includes Medical and Healthcare, Food and Beverage, Pharmaceuticals, Electronics and Semiconductor Manufacturing, Chemical and Petrochemical, Aerospace, Environmental and Water Treatment, etc.

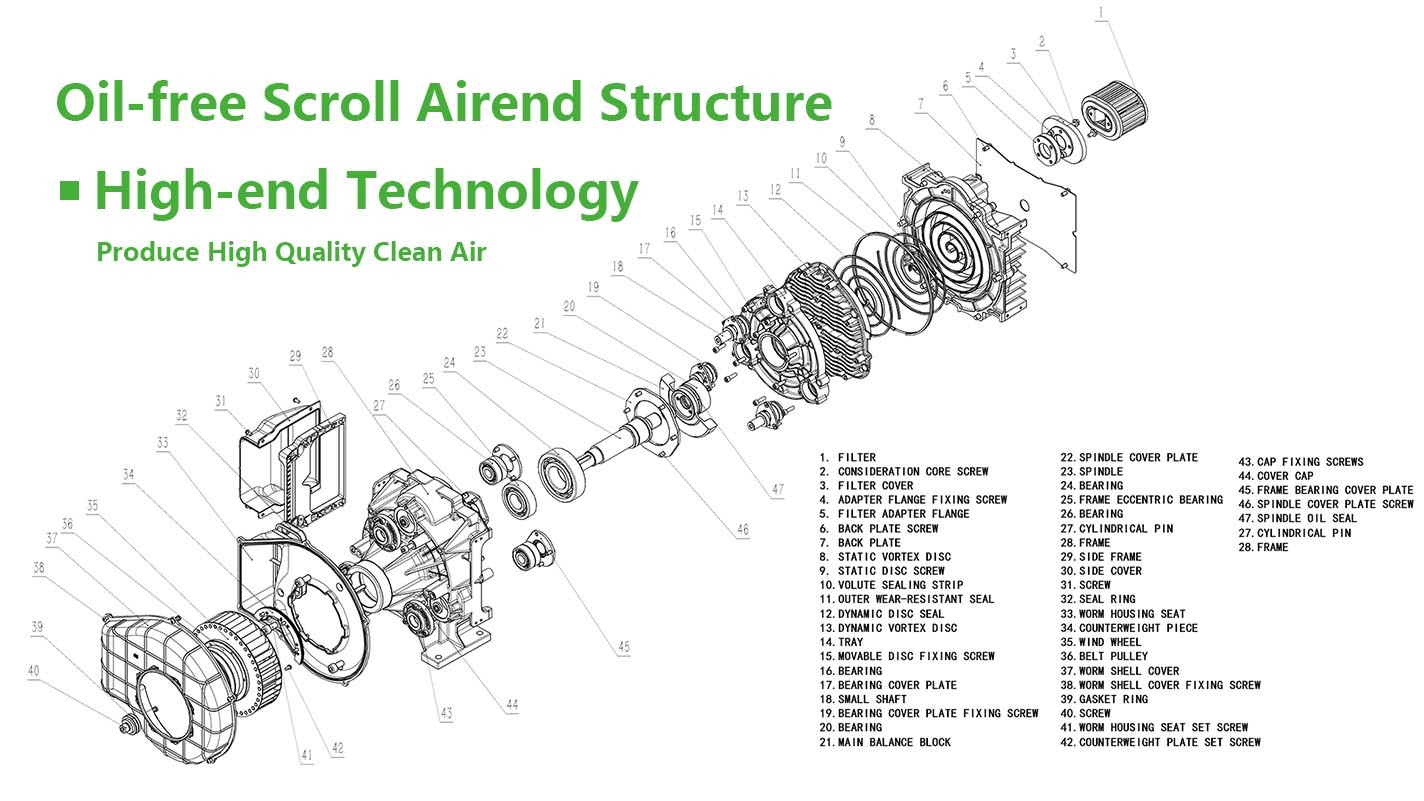

Structure of Scroll Airend

Scroll air-end consists of several critical parts that work together to compress gas efficiently. Below is a detailed breakdown of Scala brand airend.

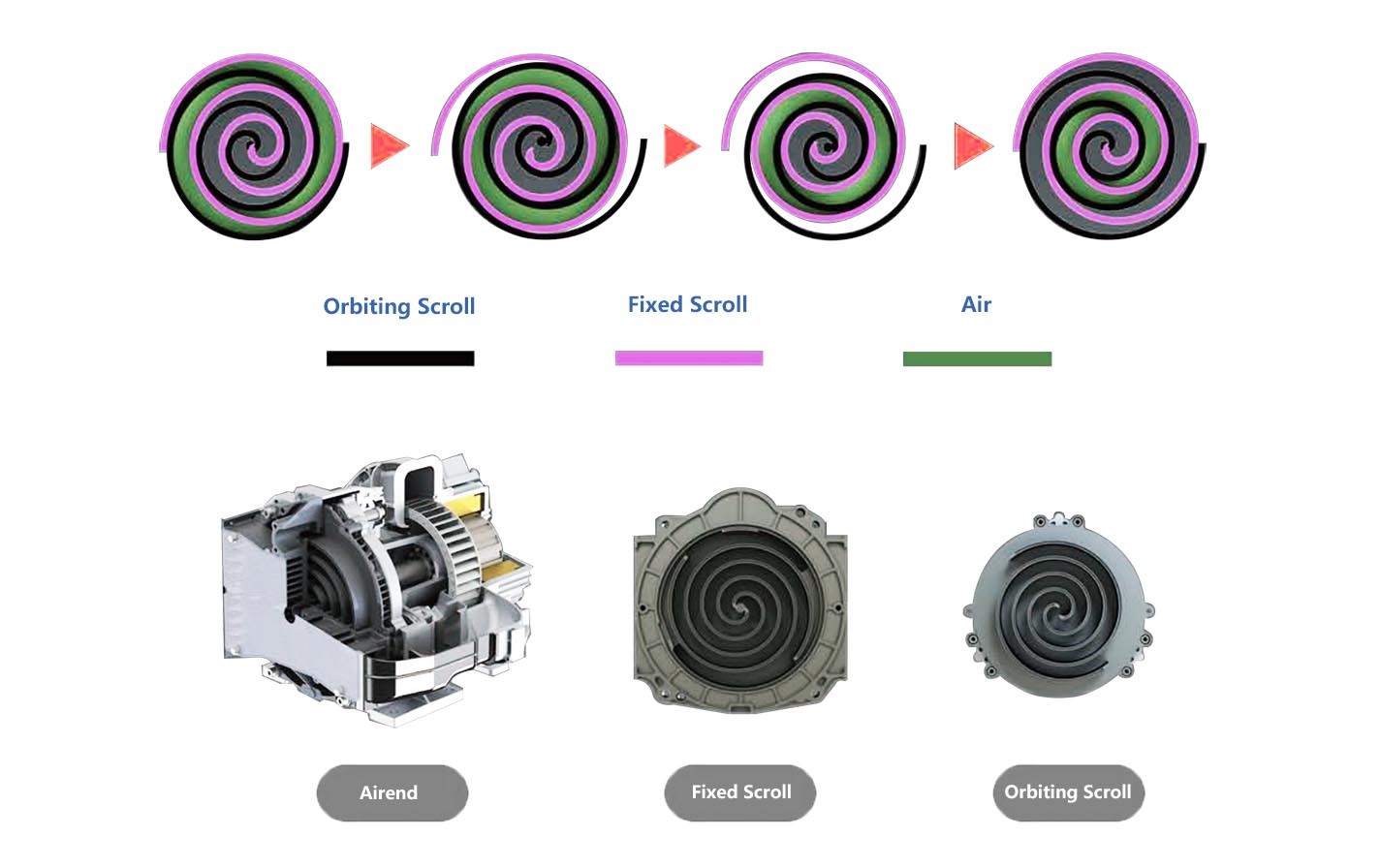

Working Principle

Basic Principle:

A scroll air-end consists of two spiral-shaped scrolls: one fixed scroll (stationary) and one orbiting scroll (movable). The orbiting scroll moves in a small circular motion (without rotating) relative to the fixed scroll, creating a series of gas pockets between the two scrolls. As the orbiting scroll moves, these pockets progressively decrease in volume, compressing the gas trapped inside.

Compression Process:

Intake Phase: Gas enters the outer pockets of the scrolls through the intake port.

Compression Phase: The gas pockets move toward the center of the scrolls, reducing in volume and increasing in pressure.

Discharge Phase: The compressed gas is discharged through the center outlet port.

Specifications

Belt-driven Airend

| Model | Power kW (HP) | Pressure Mpa | RPM | Air Flow L/min | Outlet | Dimension mm | Weight Kg |

SG02T | 3 (4) | 0.8 | 3000 | 300 | Rp 3/8 | 404x330x292 | 16 |

1.0 | 2700 | 260 | |||||

SG03T | 2.2 (3) | 0.8 | 2700 | 240 | Rp 3/8 | 414x325x293 | 15 |

1.0 | 2400 | 200 | |||||

SG04T | 3 (4) | 0.4 | 2850 | 440 | Rp 3/8 | 345x289x263 | 16 |

SG05T | 3.7 (5) | 0.8 | 3000 | 400 | Rp 3/8 | 446x341x311 | 23 |

1.0 | 2800 | 350 | |||||

SG06T | 5.5 (7.5) | 0.8 | 3150 | 600 | G 1/2 | 445x406x365 | 29 |

1.0 | 2800 | 505 | |||||

SG07T | 5.5 (7.5) | 0.4 | 2800 | 1000 | G 3/4 | 434x406x365 | 30 |

SG08T | 7.5 (10) | 0.8 | 3450 | 800 | G 1/2 | 460x405x354 | 32 |

1.0 | 3000 | 700 |

Permanent Magnet Airend

| Model | Power kW (HP) | Pressure Mpa | RPM | Air Flow L/min | Outlet | Dimension mm | Weight Kg |

SG02ZP | 3 (4) | 0.8 | 3000 | 300 | Rp 3/8 | 449x325x292 | 25 |

1.0 | 2700 | 260 | |||||

SG03ZP | 2.2 (3) | 0.8 | 2700 | 240 | Rp 3/8 | 434x325x287 | 22 |

1.0 | 2400 | 200 | |||||

SG04ZP | 3 (4) | 0.4 | 2850 | 440 | Rp 3/8 | 345x289x263 | 25 |

SG05ZP | 3.7 (5) | 0.8 | 3000 | 400 | Rp 3/8 | 500x355x312 | 36 |

1.0 | 2800 | 350 | |||||

SG06ZP | 5.5 (7.5) | 0.8 | 3150 | 600 | G 1/2 | 500x387x343 | 42 |

1.0 | 2800 | 505 | |||||

SG07ZP | 5.5 (7.5) | 0.4 | 2800 | 1000 | G 3/4 | 484x389x365 | 43 |

SG08ZP | 5.5 (7.5) | 0.8 | 3400 | 800 | G 1/2 | 530x386x342 | 45 |

1.0 | 3000 | 700 |

15 products found

ViewShowcase

Low Noise 2 bar Oxygen air compressor, 1100 Watt, Oil Free Scroll air Compressor for 10 Liter Oxygen Generator, power frequency motor.

1.1kw 2bar Mini compressor Oil free scroll Oxygen generation oxygen production air compressor SG09ZY

Low Noise 2 bar Oxygen air compressor, 1100 Watt, Oil Free Scroll air Compressor for 10 Liter Oxygen Generator, power frequency motor.

1.1kw 2bar Mini compressor Oil free scroll Oxygen generation oxygen production air compressor SG09ZY

Low Noise 2 bar Oxygen air compressor, 1100 Watt, Oil Free Scroll air Compressor for 10 Liter Oxygen Generator.

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

5.5kw 7.5HP 8bar 10bar Oil Free Scroll air End for Iwata Hitachi Atlas Scroll air Compressor Replace

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

Oil-free airend is the core component of an oil-free air compressor, designed to deliver clean, high-purity compressed air for medical, pharmaceutical, nitrogen generator, oxygen generator.

Navigation

News

- laboratory liquid nitrogen generator delivered to Tibet College of Agriculture and Animal HusbandryRecently, our company successfully supplied a self-developed laboratory liquid nitrogen generator for the Plant College of Tibet University of Agriculture and Animal Husbandry, with a liquid nitrogen output of > 20 liters per day.

- Hangzhou Scala officially launched silent laboratory liquid nitrogen generatorAs a professional laboratory liquid nitrogen solution provider, Hangzhou Scala recently officially launched a new integrated liquid nitrogen generator, the equipment is small, low noise, high degree of automation, easy to use and maintain. After more than a year of internal testing, all parameters have met the expected requirements.